Excavators play a crucial role in solid waste management applications. These are required for efficient and safe handling various waste materials, such as construction debris, municipal waste, and recyclables. However, operating an excavator in solid waste applications requires specific knowledge and skills to ensure optimal performance and minimise risks.

In this blog, we will discuss the essential do’s and don’ts for excavator operating in solid waste applications which an operator must be aware of and always keep a close watch to ensure such best practices are followed at site.

Do’s for Excavator Operation in Solid Waste Management

1. Greasing of Pin Bush

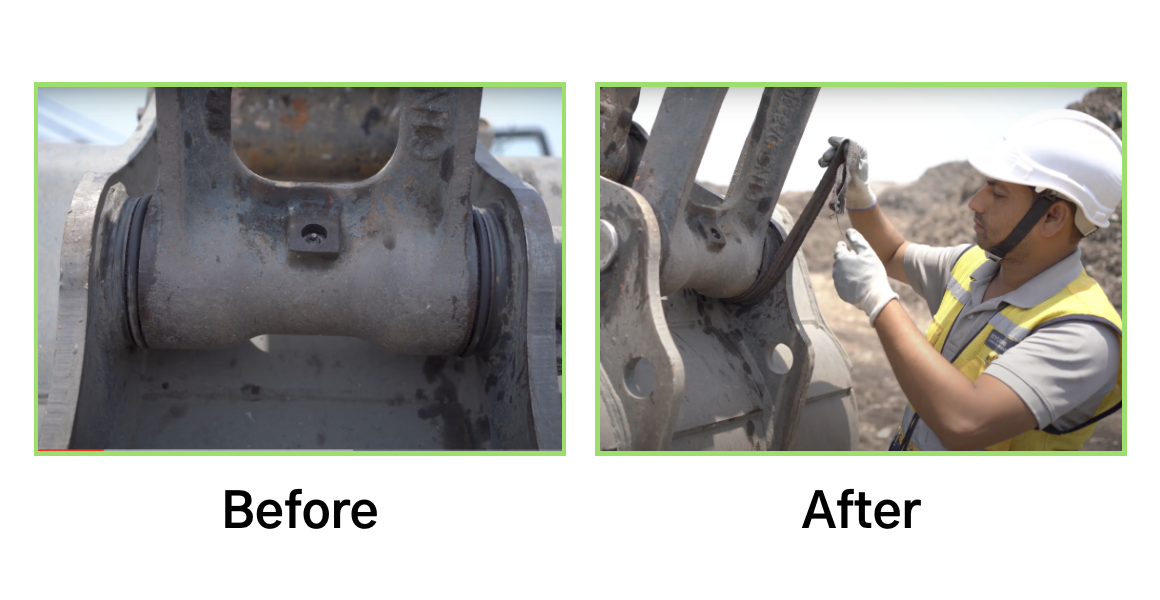

Regularly greasing the pin bush every 8 hours with genuine grease is crucial for maintaining high productivity. Even after 8 hours of periodic greasing, there is a possibility that small dust particles may enter the pin bush greasing and cause chemical reactions, leading to erosion.

To address this issue, an innovative solution can be implemented by placing a felt on every pin-bush joint. This helps prevent the entry of dust particles and significantly enhances the lifespan of the pin and bush components.

2. Cylinder Rod Cleaning

In solid waste applications, it is essential to clean the cylinder rods periodically. Regular cleaning of the cylinder rods offers several benefits, such as increasing their lifespan, preventing seal kits from experiencing leakages and maximising machine uptime. By removing dirt, debris, and other contaminants from the cylinder rods, you can ensure smooth operation, reduce the risk of damage to the rods and seals, and maintain the overall efficiency of the equipment.

Don’ts for Excavator Operation in Solid Waste Management

1. Avoid Choking on the Radiator

The radiator is susceptible to blockage when used in solid waste applications. Dust and debris, such as plastic waste particles, can adhere to the radiator and obstruct its function. To prevent choking, it is advisable to place a net over the radiator to prevent larger polythene materials from entering and causing blockages. Implementing this preventive measure enhances the radiator’s efficiency, and the time between cleanings is increased.

In general applications, radiator cleaning is not required between 100~ 200 operating hours. However, in solid waste management, regular monitoring is crucial. If the radiator fins become choked, clean it using high-pressure air. Also, add coolant if the engine overheats or the coolant level rises due to evaporation to maintain optimal engine efficiency and prevent overheating.

2. Avoid Choking Electrical Circuits & Battery Vents

Regular cleaning of electrical circuits and battery vents is essential to prevent obstruction and potential short circuits. Over time, dust, dirt, and other contaminants can accumulate on electrical circuits and battery vents, hampering their performance and potentially leading to electrical faults.

To avoid this, periodic cleaning should be done to remove any accumulated debris and ensure the proper functioning of the electrical system and battery vent.

3. Avoid Waste Trapping in Undercarriage

The accumulation of waste in the undercarriage is another issue to avoid. When waste, especially waste containing various chemicals, adheres to different components of the undercarriage, such as upper rollers, track guards, sheet metal, and plates, it can lead to the formation of rust and corrosion.

To prevent this, it is crucial to clean the undercarriage using pressure water regularly. By doing so, waste accumulation is minimised, reducing the risk of rust formation. Regular undercarriage cleaning helps maintain the integrity and performance of the undercarriage components, ensuring smooth operation and prolonging their lifespan.

Final Thoughts

Operating an excavator in solid waste management applications demands adherence to specific do’s and don’ts to ensure safety, efficiency, and compliance with waste management regulations. Following the recommended practices discussed in this blog post, operators can minimise risks, optimise performance, and contribute to effective waste management and environmental preservation efforts. Remember, safety should always be the top priority when working in challenging waste management environments.

While the above-mentioned tips are critical to ensure the health of an excavator in solid waste management, choosing the highest quality excavator is equally crucial. HD Hyundai Construction Equipment India offers the best excavators for solid waste management application. Hyundai excavators are built to ensure rigorous workloads and offer excellent productivity to operators. Additionally, operators can leverage our maintenance services to ensure optimum output for the longest time, justifying their investment in excavators.